Overcoming Challenging Industrial Problems

Foul business

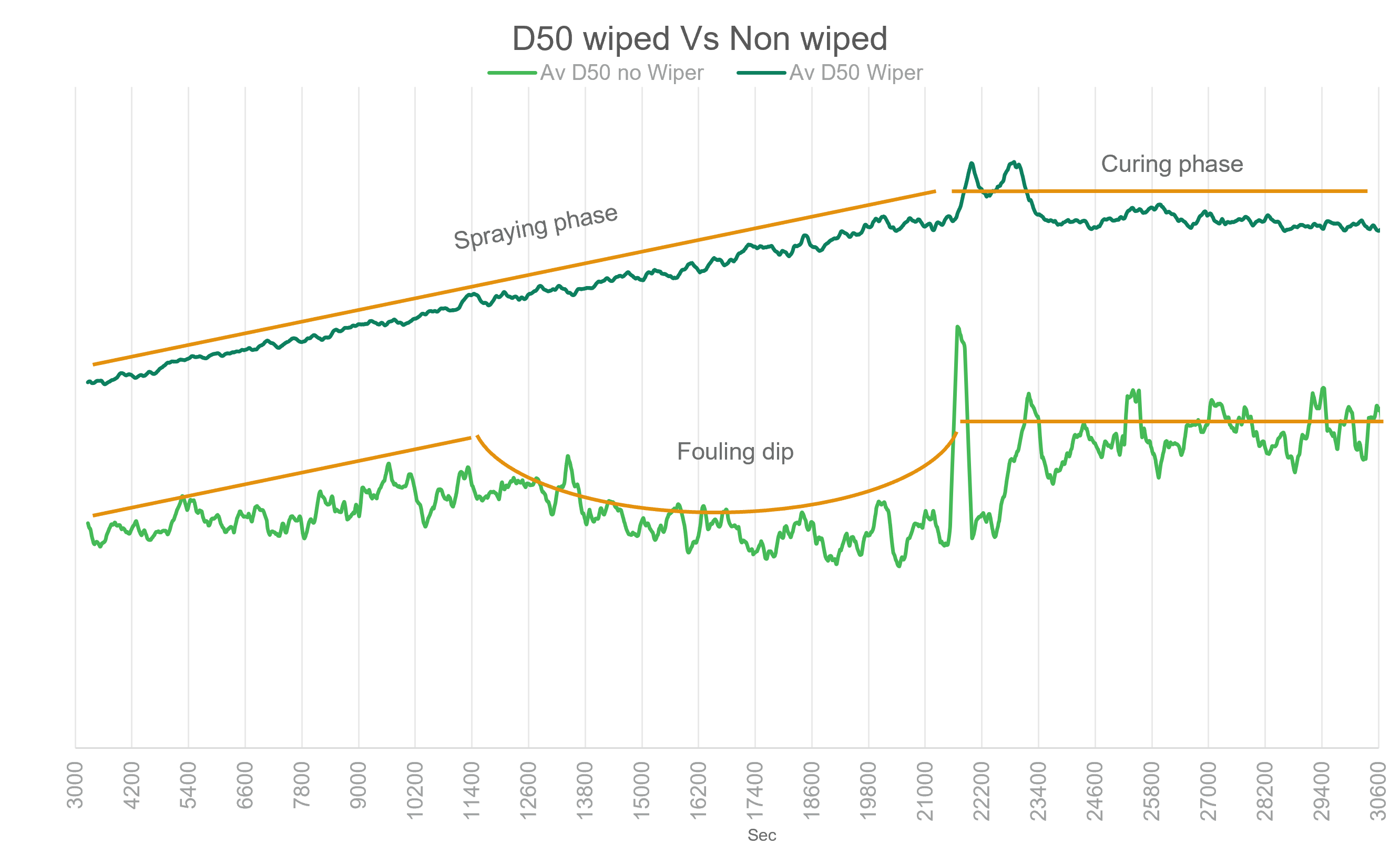

In the manufacturing industry, window fouling is a common problem that can interfere with the accurate measurement of critical quality data. Window fouling occurs when particles, liquids, or other materials build up on the windows of sensors, making it difficult for the sensors to collect accurate readings. This can lead to costly production delays and product recalls.

Our partner company, Innopharma Technology specializes in developing smart solutions for industrial problems. A recently developed wiper system was put to the test with a customer to help overcome the problem of window fouling. The wiper system is designed to automatically clean the windows for sensors, keeping them free of debris and ensuring that they can collect accurate readings. In this case, the wiper system was used with Eyecon2 a particle size and shape analyser.

Clean clear and under control

The wiper system is a GMP design made to compile with the regulatory requirements for the Pharmaceutical and Food industry. Its construction is made up of several components, including a pneumatic actuator, a wiper arm, a plastic wiper blade

and a control unit. The actuator drives the wiper blade, which moves across the window, removing any debris that is present. The wiper system is designed to be highly effective, with the angle of attack on the plastic blade kept

under constant tension to ensure the window is scrapped clean. It can be used in a variety of industrial applications, including pharmaceutical manufacturing, food, and chemical production.

Innopharama Technology's wiper system is a valuable tool for overcoming the challenges of window fouling. It is a reliable and efficient way to keep sensors clean and ensure that they can collect accurate readings. This can help to improve product quality,

reduce production costs, and prevent costly recalls.

Here are some of the benefits of using our custom built wiper system:

Ensures accurate readings from sensors.

Prevents production delays and product recalls.

Easy to install and use

GMP design that can be CIP or Ultrasonicated.

If you are facing the problem of window fouling in your manufacturing process, Innopharma Technology's wiper system is a great solution. Contact them today to learn more about how their product and services that can help you improve your production efficiency.

DR SEAN COSTELLO

Director

Sean leads the Technology Division of Innopharma, applying Industry 5.0 solutions to pharmaceutical, food and fine chemical industries. He is responsible for Innopharma’s R&D programme. Sean sits on the Technology Advisory Committee for the Enterprise Ireland/IDA Technology Centre for Pharmaceutical Manufacturing Solutions, PMTC and is involved in the SFI Research Centre for Pharmaceuticals, SSPC. Prior to Innopharma, Sean was a founder of Medical Device company and University spin-out SlidePath, subsequently acquired by Leica Biosystems, which developed cloud-enabled AI-driven diagnostic decision support and automated workflow solutions for clinical histopathology, pharma drug discovery and drug safety. Sean holds a PhD in Pathology Imaging and Medical Informatics and a BSc in Biotechnology.

Read more...Our Impact

INSIGHT

Best practice in Public-Private Partnership

Addressing the digital skills gap is urgent and immense in scale...

READ

CASE STUDY

Equipping Graduates in Africa with Skills for a New Technological Era …

Apply now for this short course in partnership with The South African Radio Astronomy Observatory (SARAO).

READINSIGHT

Future skills in high-tech manufacturing...

The key upcoming changes in advanced manufacturing and how automation will disrupt not only Ireland but globally.

READ